INVENTORY MANAGEMENT SYSTEM IN INDIA

Monitor and have an accurate record, from order placement of raw materials from the vendors to the finished products delivered to your customer using a robust Inventory Management System in India.

What you can do with our Inventory Management System?

1. Maintain a balance between too much and too little inventory.

2. Filter or categorize the products based on type, name, price, supplier and so on for migration between different groups and channels.

3. Ensure uninterrupted production process, as raw materials and assemblies are available timely.

4. Transportation of materials between various locations like warehouse, stocking areas, manufacturing units could be tracked accurately.

5. Complex process during picking, packing and shipping would be made at ease.

6. Ensure popular items remain in stock.

salesenquiry@uniprotech.co.in

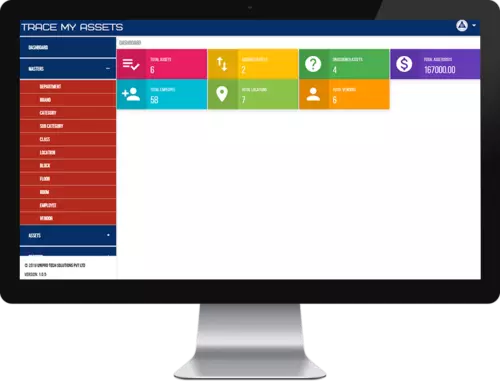

Unipro’s Barcode and RFID based Inventory Management System in India

Many organizations face issues in maintaining their inventory and monitoring them throughout the production process until the goods get dispatched to the customer, improper handling of inventories may lead to deadline extension that might subject to call off the project. But having a sophisticated inventory management system from Unipro can ease your stocking, production, and dispatching process.

Unipro’s Inventory Management system was a combination of process, procedure, and Technology that monitors and maintains the stocked items, Production process, and Dispatching process.

How does the Inventory Management System in India Addresses the Challenges Faced by our Serving Industries?

- The transformation from manual to digital inventory management system would help the organization to maintain accurate inventory records.

- With an EOQ system, an organization will save unnecessary inventory costs such as ordering, holding, and shortage costs.

- Barcode and RFID system for inventory management would ease the process of data capturing in real-time.

Modules Incorporated in the Inventory Management System

Those requirements would be fulfilled by our inventory management system in India and its modules are designed in a way that it would meet the future market scenario.

- GRN Upload

- Raw Material QC

- Receiving from QC

- Item Put away

- Production Line Request

- Production

- Production Daily Entry

- Finished Goods QC

- Pallet Entry

- Dispatch

- Internal Transfer

- Wastage Entry

Features and Benefits of Inventory Management System

- Inventory management gets simplified

- Reduce paper work and human error

- Improved data accuracy

- Gain more control over complete process

- Increased efficiency and productivity

- Instant inventory reports

- Increased throughput

- Highly customized application based on customer request

- ERP integration

Inventory Management Process

- The raw materials/goods are received at the warehouse and put into the stock areas.

- In the case of small business, the goods are directly put in the shelves. Here the receiving location is not considered.

- In the case of wholesale business, the received items would be the finished products.

- For the production process, the materials are picked from the stock areas based on some product-specific rules and moved to the facilities.

- The finished goods may put back to the stock areas before shipping or shipped directly to the customer.

During the process, Unipro’s inventory management system handles many data from “Fetching the data from Oracle for GRN information to verifying the dispatching information before shipment”. Also, to keep track of goods it handles attributes like PO numbers, serial numbers, cost of goods, the number of goods, dates when it went for production and so on.

AIDC Products Required for Inventory Management System

Having only the software solution is not sufficient to perform inventory handling! appropriate hardware is required. So, to offer the complete solutions, we the authorized distributor of World’s Major like Zebra, Honeywell, Epson, Datalogic,… we supply mobile computing, data capturing, and printing devices at the nominal rate.

Meet the wide range of scanning needs with unmatched abilities

Keep your business moving with direct thermal and thermal transfer printers

Equip you workforce with mobile computing devices to drive more productivity

Get Barcode Labels, Ribbons, and RFID Tags to meet your demands

Our Other AIDC / Traceability Solutions

Optimize your warehouse operations to have increased throughput and reduced level of inventory risks.

Manage & track the raw materials, components, assemblies and finished products using Work-In-Progress tracking solution.

Perform route planning and grouping the orders to dispatch the goods & finished products in an optimized manner.

Track and monitor material movement across storage facilities to have an uninterrupted production process & eliminate excessive stocks.

Have centralized records of all your business vendors and evaluate their performance against qualitative and quantitative benchmarks!

Improve asset visibility and have complete product information start from acquisition to retirement with our Asset Tracking Software.

Track visitor movement throughout your organization and perform visitor pass creation and appointment management.

Automate and record the movement of files/documents using Barcode & RFID Technology to know the up-to-date status of the files.

CORPORATE OFFICE

Unipro Tech Solution Pvt Ltd

KNR Building, Plot No: 23&35B, Sriram Nagar,

2nd Street, Mugalivakkam Road, Porur,

Chennai-600116, Tamil Nadu, India

salesenquiry@uniprotech.co.in

+91 44 421 421 40